Permanent Sintered Samarium Cobalt Sm1co5 Sm2co17 High Working Temperature SmCo Magnet

Permanent Sintered Samarium Cobalt Sm1co5 Sm2co17 high working temperature SmCo Magnet A. Sintered SmCo Magnet The SmCo ;

Basic Info

| Model NO. | YX16-YXG32L |

| Grade | Yx16s to Yxg32L |

| Size | Depend on Customer′s Request |

| Tolerence | +/-0.1mm or Depend on Customer′s Request |

| Lead Time | 25-30days |

| Surface Treatment | No |

| Plating | Nickel |

| MOQ | Depend on Customer′s Request |

| Quality Assurance | Yes |

| Payment Method | T/T Paypal Western Union |

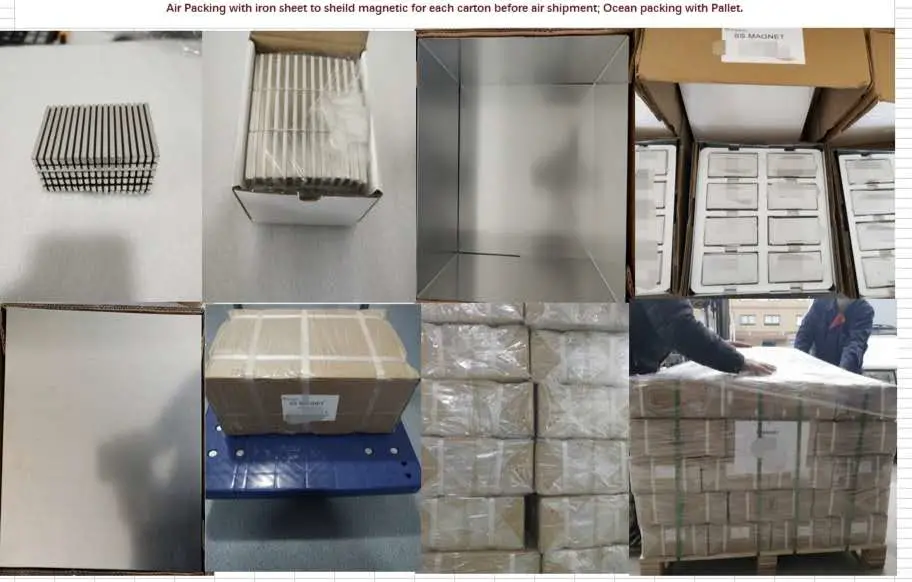

| Transport Package | Air Packing or Ocean Packing |

| Specification | Depend on customer′s reqeust |

| Trademark | SS Magnet |

| Origin | China |

| HS Code | 8505111000 |

| Production Capacity | 1000tons Per Year |

Product Description

Permanent Sintered Samarium Cobalt Sm1co5 Sm2co17 high working temperature SmCo MagnetA. Sintered SmCo Magnet

The SmCo permanent magnet has two types available: 1:5(SmCo5) & 2:17(Sm2Co17).

Samarium Cobalt (SmCo) magnets are manufactured by using powder metallurgy techniques which include stringent process controls and complicated heat treatment cycles. The composition of this alloy is approximately 35% Samarium, 60% Cobalt with the balance being Fe&Cu.

B. Application Fields:

All sorts of SmCo are used in the Electronic Magnetron, Magnetic Transmission, Magnetic Treatment, Magnistor, etc. And it's mainly applications are servo-motors, pump coupling and sensors.

C. Advantages of SmCo Magnet:

1. Superior resistance to high temperature.

2. Excellent resistance to corrosion, no coating is needs for surface protecting.

3. High working temperature.

4. SmCo is suitable for machines with high magnetic requirements and good for strict working environment requirement.

| TYPICAL PROPERTY | |||||||||||||

| MAGNETIC PROPERTIES OF SINTERED SMCO | |||||||||||||

| Material | Grade | Br | Hcb | Hcj | (BH)max | TC | Maximum working temperature | (Br) | Hcj | ||||

| SmCo5(Smpr)co5 | T | KGS | KA/m | KOe | KA/m | KOe | KJ/M3 | MGOe | ºC | ºC | %ºC | %ºC | |

| YX-16 | 0.81-0.85 | 8.1-8.5 | 620-660 | 7.8-8.3 | 1194-1830 | 15-23 | 110-127 | 14-16 | 750 | 250 | -0.050 | -0.30 | |

| YX-18 | 0.85-0.90 | 8.5-9.0 | 660-700 | 8.3-8.8 | 1194-1830 | 15-23 | 127-143 | 16-18 | 750 | 250 | -0.30 | ||

| YX-20 | 0.90-0.94 | 9.0-9.4 | 676-725 | 8.5-9.1 | 1194-1830 | 15-23 | 150-167 | 19-21 | 750 | 250 | -0.30 | ||

| YX-22 | 0.92-0.96 | 9.2-9.6 | 710-748 | 8.9-9.4 | 1194-1830 | 15-23 | 160-175 | 20-22 | 750 | 250 | -0.30 | ||

| YX-24 | 0.96-1.00 | 9.6-10 | 730-770 | 9.2-9.7 | 1194-1830 | 15-23 | 175-190 | 22-24 | 750 | 250 | -0.30 | ||

| SmCo5 | YX-16s | 0.79-0.84 | 7.9-8.4 | 612-660 | 7.7-8.3 | ≥1830 | ≥23 | 118-135 | 15-17 | 750 | 250 | -0.035 | -0.28 |

| YX-18s | 0.84-0.89 | 8.4-8.9 | 644-692 | 8.1-8.7 | ≥1830 | ≥23 | 135-151 | 17-19 | 750 | 250 | -0.040 | -0.28 | |

| YX-20s | 0.89-0.93 | 8.9-9.3 | 684-732 | 8.6-9.2 | ≥1830 | ≥23 | 150-167 | 19-21 | 750 | 250 | -0.045 | -0.28 | |

| YX-22s | 0.92-0.96 | 9.2-9.6 | 710-756 | 8.9-9.5 | ≥1830 | ≥23 | 167-183 | 21-23 | 750 | 250 | -0.28 | ||

| YX-24s | 0.96-1.00 | 9.6-10 | 740-788 | 9.3-9.9 | ≥1830 | ≥23 | 183-199 | 23-25 | 750 | 250 | -0.28 | ||

| (SmGd)Co5 | LTc(YX-10) | 0.62-0.66 | 6.2-6.6 | 485-517 | 6.1-6.5 | ≥1830 | ≥23 | 75-88 | 9.5-11 | 750 | 300 | Temp range | Br%ºC |

| 20-100ºC | +0.0156%ºC | ||||||||||||

| 100-200ºC | +0.0087%ºC | ||||||||||||

| 200-300ºC | +0.0007%ºC | ||||||||||||

| ce(coFecu)5 | YX-12 | 0.70-0.74 | 7.0-7.4 | 358-390 | 4.5-4.9 | 358-478 | 4.5-6 | 80-103 | 10-13 | 450 | 200 | ||

| Sm2(CoFecuzr)17 | YXG-24H | 0.95-1.02 | 9.5-10.2 | 692-764 | 8.7-9.6 | ≥1990 | ≥25 | 175-191 | 22-24 | 800 | 350 | -0.025 | -0.20 |

| YXG-26H | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | ≥1990 | ≥25 | 191-207 | 24-26 | 800 | 350 | -0.030 | -0.20 | |

| YXG-28H | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | ≥1990 | ≥25 | 207-220 | 26-28 | 800 | 350 | -0.035 | -0.20 | |

| YXG-30H | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥1990 | ≥25 | 220-240 | 28-30 | 800 | 350 | -0.20 | ||

| YXG-32H | 1.10-1.13 | 11.0-11.3 | 812-860 | 10.2-10.8 | ≥1990 | ≥25 | 230-255 | 29-32 | 800 | 350 | -0.20 | ||

| YXG-22 | 0.93-0.97 | 9.3-9.7 | 676--740 | 8.5-9.3 | ≥1433 | ≥18 | 160-183 | 20-23 | 800 | 300 | -0.020 | -0.20 | |

| YXG-24 | 0.95-1.02 | 9.5-10.2 | 692-764 | 8.7-9.6 | ≥1433 | ≥18 | 175-191 | 22-24 | 800 | 300 | -0.025 | -0.20 | |

| YXG-26 | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | ≥1433 | ≥18 | 191-207 | 24-26 | 800 | 300 | -0.030 | -0.20 | |

| YXG-28 | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | ≥1433 | ≥18 | 207-220 | 26-28 | 800 | 300 | -0.035 | -0.20 | |

| YXG-30 | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥1433 | ≥18 | 220-240 | 28-30 | 800 | 300 | -0.20 | ||

| YXG-32 | 1.10-1.13 | 11.0-11.3 | 812-860 | 10.2-10.8 | ≥1433 | ≥18 | 230-255 | 29-32 | 800 | 300 | -0.20 | ||

| YXG-26M | 1.02-1.05 | 10.2-10.5 | 676-780 | 8.5-9.8 | 955-1433 | 12-18 | 191-207 | 24-26 | 800 | 300 | -0.20 | ||

| YXG-28M | 1.03-1.08 | 10.3-10.8 | 676-796 | 8.5-10.0 | 955-1433 | 12-18 | 207-220 | 26-28 | 800 | 300 | -0.20 | ||

| YXG-30M | 1.08-1.10 | 10.8-11.0 | 676-835 | 8.5-10.5 | 955-1433 | 12-18 | 220-240 | 28-30 | 800 | 300 | -0.20 | ||

| YXG-32M | 1.10-1.13 | 11.0-11.3 | 676-852 | 8.5-10.7 | 955-1433 | 12-18 | 230-255 | 29-32 | 800 | 300 | -0.20 | ||

| YXG-24L | 0.95-1.02 | 9.5-10.2 | 541-716 | 6.8-9.0 | 636-955 | 8-12 | 175-191 | 22-24 | 800 | 250 | -0.025 | -0.20 | |

| YXG-26L | 1.02-1.05 | 10.2-10.5 | 541-748 | 6.8-9.4 | 636-955 | 8-12 | 191-207 | 24-26 | 800 | 250 | -0.035 | -0.20 | |

| YXG-28L | 1.03-1.08 | 10.3-10.8 | 541-764 | 6.8-9.6 | 636-955 | 8-12 | 207-220 | 26-28 | 800 | 250 | -0.20 | ||

| YXG-30L | 1.08-1.15 | 10.8-11.5 | 541-796 | 6.8-10.0 | 636-955 | 8-12 | 220-240 | 28-30 | 800 | 250 | -0.20 | ||

| YXG-32L | 1.10-1.15 | 11.0-11.5 | 541-812 | 6.8-10.2 | 636-955 | 8-12 | 230-255 | 29-32 | 800 | 250 | -0.20 | ||

| (SmEr)2(CoTM)17 | LTC(YXG-22) | 0.94-0.98 | 9.4-9.8 | 668-716 | 8.4-9.0 | ≥1433 | ≥18 | 167-183 | 21-23 | 840 | 300 | Temp range | Br%ºC |

| -50-25ºC | +0.005%ºC | ||||||||||||

| 20-100ºC | -0.008%ºC | ||||||||||||

| 100-200ºC | -0.008%ºC | ||||||||||||

| 200-300ºC | -0.011%ºC | ||||||||||||

| PHYSICAL & MECHANICAL PROPERTIES | |||||||||||

| Physical Characteristics | |||||||||||

| Parameter Name | Unit | SmCo 1:5 | SmCo 2:17 | ||||||||

| Density | G/Cm3 | 8.3 | 8.4 | ||||||||

| Curie Temperature | K | 1000 | 1100 | ||||||||

| Vickers hardness | MPa | 450-500 | 550-600 | ||||||||

| Compressing Strength | MPa | 1000 | 800 | ||||||||

| Electronic Resistivity | Ω.Cm | 5-6&Times;10-5 | 8-9&Times;10-5 | ||||||||

| Bending Strength | MPa | 150-180 | 130-150 | ||||||||

| Stretching Strength | MPa | 400 | 350 | ||||||||

| Hot Coefficient Of Expansion | (10-6/ºC) | ‖6⊥12 | ‖6⊥11 | ||||||||

| Note: The Above Specific Numbers Help To Consult, Not to Be The Judging Basis | |||||||||||

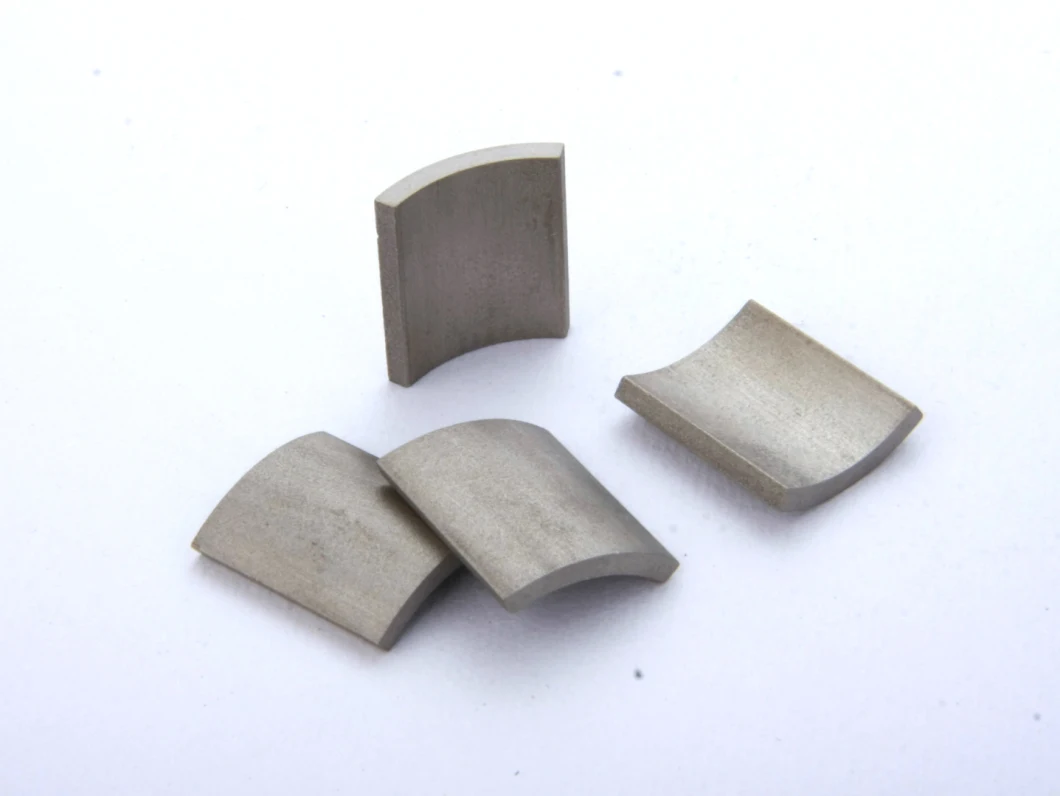

Arc shape Permanent SmCo Magnet for rotor

Product Description:

| Product name: | SmCo Magnet |

| Shape: | Cylinder/Rod ( Disc, Block, Ring, Countersunk, Segment, Trapezoid, Irregular shapes are available, Customized shapes for Sintered NdFeB Magnet are also available) |

| Grade: | From Sm1Co5 YX16 to Sm2Co17 YXG32L |

| Size | Various sizes,which depend on customer's request |

| Surface treatment: | No coating or depend on customer's request |

| MOQ: | 10Pcs |

Advantage: Competitive prices based on high quality,fast lead time and excellent service

Transportation: By air or ocean shipment from Ningbo or Shanghai to all around the world

Lead time:15-30days,which depend on Qty customers need.

We can provide you all customized magnetd, magnetic applications and design them for you too!

Solutions for cost saving for you to choose the most suitable magnetic products.

Welcome to your enquiry anytime and we will reply you within 24hours in time.

Contact Person:Cary Li

You may also like

Send inquiry

Send now